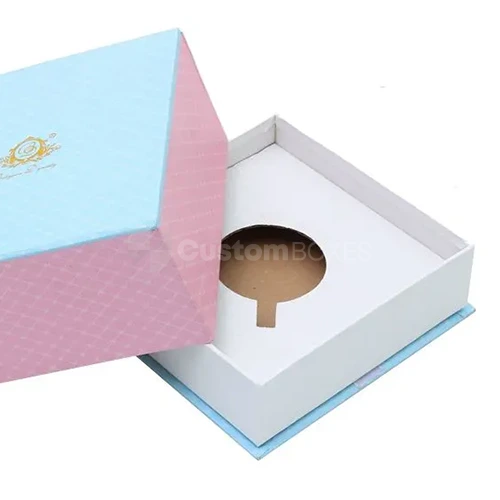

Perfectly Fit Your Products With Custom Die Cut Box Inserts

Custom die-cut box inserts are a great way to protect and showcase your products professionally and stylishly. Choose from various materials and finishes to create a custom packaging solution that perfectly represents your brand.

Impress Your Customers

Are you trying to leave a lasting impression on your clients? So our die-cut box inserts are the perfect solution. They give clients a great unpacking experience with their professional style and superb security.

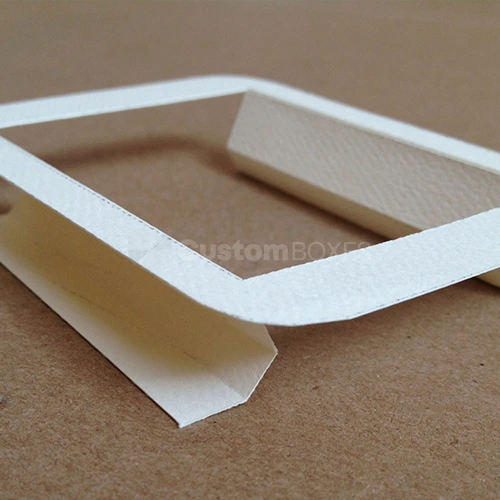

Protect Your Products With Die Cut Cardboard And Corrugated Inserts

Die-cut cardboard and corrugated inserts are designed to protect your products during shipping and handling while providing a professional look that enhances your brand image. With our expert team and customizable options, we can create Die Cut Corrugated Inserts that perfectly fit your product dimensions, ensuring maximum protection and a seamless unboxing experience for your customers.

Die-Cut Foam Packaging Inserts

Want a high-end packaging option for your delicate products? Our die-cut foam packaging inserts offer superior protection against shock, vibration, and impact during shipping and handling.

With our expert team and customizable options, we can create inserts that perfectly fit your product dimensions, ensuring maximum protection and a professional look. Invest in our Die-cut foam packaging inserts, and die-cut inserts give your products the protection they deserve.

Why Choose Us?

U custom boxes offer various packaging services, including custom packaging design, printing, and manufacturing. We pride ourselves on our finest quality materials, expert craftsmanship, and attention to detail. We specialize in Boxes sleeves, Cone sleeves, and Die cut inserts, Dispense boxes, Five panel hanging boxes, Happy meal boxes, Mailer box cardboard, Pillow boxes, PVC window box, Reverse tuck end boxes, Roll end box cardboard, Sealand boxes, Snap lock box, straight tuck end boxes, and wrapping paper while maintaining a high-quality standard.

Our creative team of professional designers works closely with our clients to ensure their packaging needs are met with custom solutions that perfectly represent their brand. Contact us today for a free custom quote and experience why we are the preferred custom packaging company for businesses.